We process products, mainly by cutting them, using processing machines withCO2 laser beamsusing near-infrared rays.

Processing of various shapes can be achieved by combining CO2 laser beams and industrial control systems.

The advantages include that smooth cutting surfaces can be obtained, high-speed processing becomes possible since energy closer to the surface temperature of the sun is used, and not only mass production, but also high-mix low-volume production or mass production of small-lot products or products with complicated shapes become possible.

|

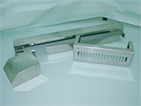

●Characters with Complicated Shapes |

The NC-controlled processing enables flexible shaping covering simple profiles up to complicated profiles.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gear Shapes

Gears can be processed with precision equivalent to machine processing. |

|

Slit Processing

This processing makes the most of the characteristics of the laser beam that offers small cutting width.

0.7 mm-wide 0.2 mm slits. |

|

Complicated Shapes

Complicated shapes can be processed as intended by utilizing NC data. |

|

Polished Material Processing

Processing of polished materials can be performed without making scratches on them thanks to the use of the non-contact type of working machines. |

●Smooth Cutting Surface and Plate Thickness |

Basically, we use N2 for stainless steel as an assist gas, N2 for mild steel up to thickness of 3.2 t, and O2 for mild steel with thicker plate. Thus, we cut materials having various plate thicknesses while ensuring smooth cutting surfaces.

We are positively tackling profiles and materials that cannot be processed by other companies.

Please do not hesitate to make inquiries to us or request estimates from us.

|

|

|

●Thick Materials |

For stainless steel, plate thickness of up to 20 mm can be cut.

Even products with complex profiles or large size can be processed.

|

|

|

|

|

|

|

|

|

|

|

|

|

SUS 20mm

Laser cutting can provide higher precision than plasma even with a thick plate, which contributes to saving of subsequent processes. |

|

Aluminum 12.0 mm

Smooth cutting of aluminum, which was conventionally difficult with laser, is no longer a problem. |

|

Mild Steel 16 mm

Mild steel can also be cut smooth. |

|

Precision Sheet Metal Working |

Do you have products that require bending or welding after cutting and processing?

We realize quick delivery through lump-sum production at a location, rather than working with cutting, bending, and welding in different locations. |

●Major Bending Work |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Box Bending

Even bending and complex bending can be ensured through NC control. |

|

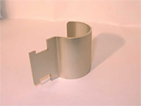

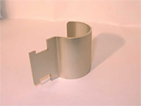

“R”-Bended Product

“R” bending can also be performed through NC control. For rolling, a dedicated roll processing machine will be used. |

|

Hemming

Hemming is mainly used for foodstuff containers and similar products. |

|

Step Bending

A dedicated mold may sometimes be required for step bending. |

|

We respond to customer needs with stable and reliable technologies accumulated in jobs related to semiconductors. |

|

●Weld Scale Removing/Finishing |

We respond to customer needs with reliable technologies covering quick removal of weld scale with CLINOX Pro finished with skilled engineering.

|

|

|

●Weld Scale Removing/Finishing

|

|

We respond to customer needs with reliable technologies covering quick removal of weld scale with CLINOX Pro finished with skilled engineering.

|

|

|